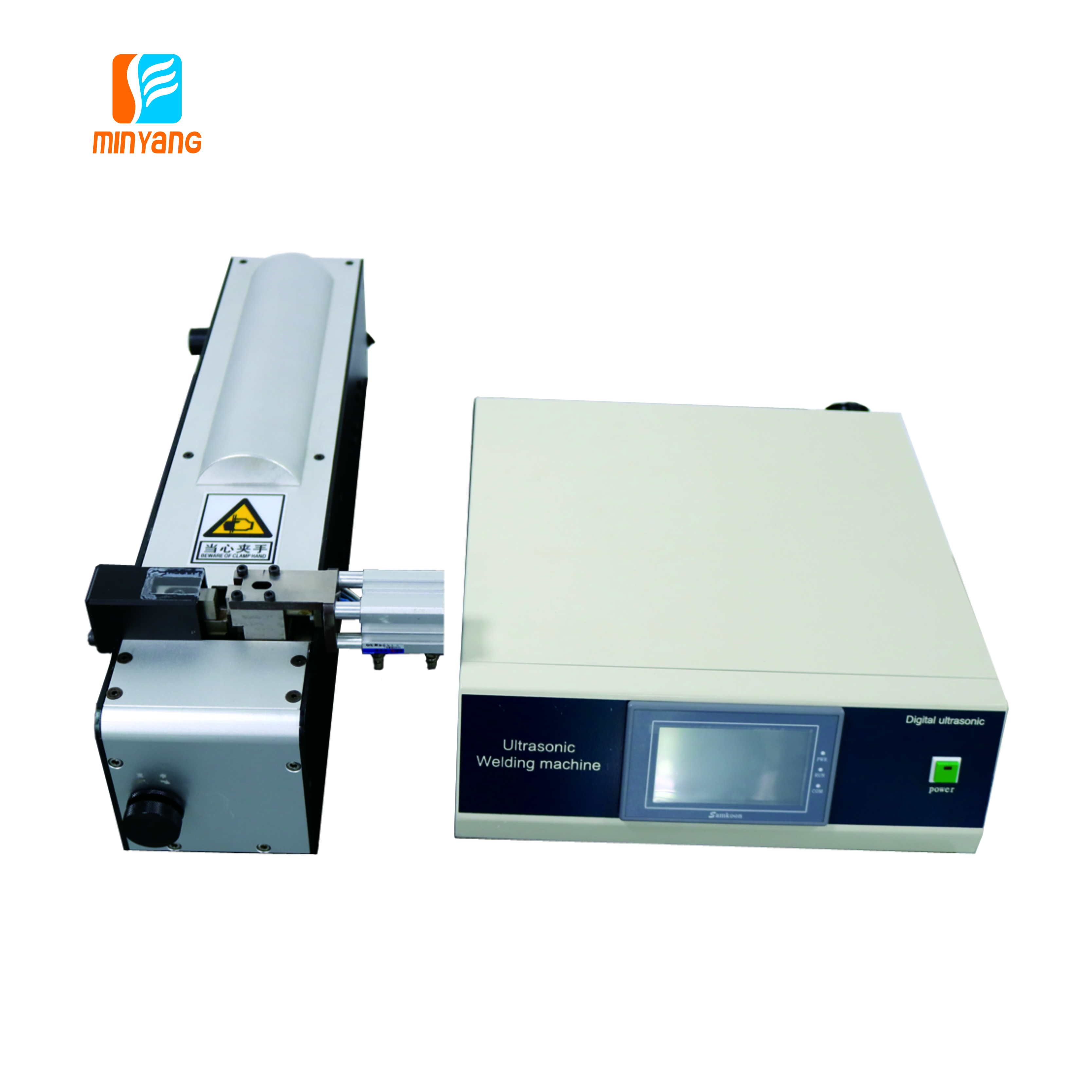

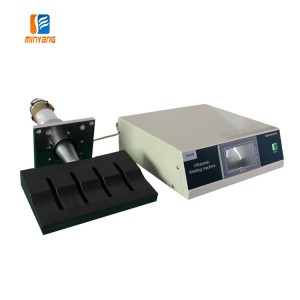

Intelligent Ultrasonic Metal Welding Machine for Wires

Specification

| Model | MY-MZN2040-S |

| Frequency | 50/60KHz |

| Power | 3000-6000w |

| Voltage | 110/220v |

| Net Weight | 110kg |

| Machine Size | 70x60x80CM |

| Warranty | 1 year |

| Working mode | Time mode and the energy mode |

Features

During the metal welding process, tens of thousands of high-frequency vibration waves per second is transferred to two metal workpiece surface, and then impose a certain pressure on it, so that the metal surface friction and the formation of fusion between molecular layers, to achieve the purpose of metal welding.

Here are the features of the ultrasonic metal welding machine

High fusion strength;

Close to cold processing, workpiece no annealing, no oxidation trace.

After welding, the electrical conductivity is good, and the resistance is better than other welding processes.

Low requirements for welding metal surface, oxidation or electroplating can be welded.

Short welding time and high welding efficiency. Do not need any flux, gas, solder.

Welding without spark, eco-friendly.

Two welding mode to be chosen, time welding mode and the energy welding mode.

Applications

Ultrasonic metal welder can weld copper, silver, aluminum, nickel and other non-ferrous metal wire or thin sheet materials for single point welding, multi-point welding and short strip welding. Can be widely used in silicon controlled lead, fuse piece, electrical lead, lithium battery pole piece, pole ear welding.

Factory Show

Certification

FAQ

A: Yes, we can. The mould could be customized based on your samples, the voltage can be 110V or 220V, the plug can be replaced with yours before shipment.

A: Please provide the material, size of your product and your welding requirements, such as waterproof, tight air, etc. You'd better provide product 3D drawings , and we can help to check if the drawings need to be changed. So that the plastic product design could meet the requirements of ultrasonic welding technology.