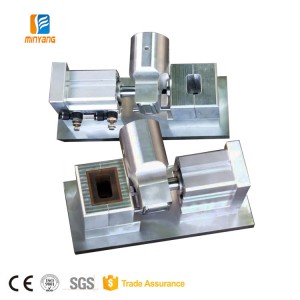

Ultrasonic Customize Horn Mold for Plug Welding

Specification

| Model | MY-MJ1520-9-S |

| Frequency | 15-40k |

| Power | 800-8000w |

| Voltage | 110v/220v |

| Welding time | 0.01-9.99s |

| Service | OEM/ODM |

Features

The ultrasonic mould is made of high quality imported material, and the life and manufacturing precision are comparable to similar products in Europe and America. We can manufacture steel and titanium welding heads and tips at any frequency, and can be matched with other companies' products. We can provide customize mould for your requirements..

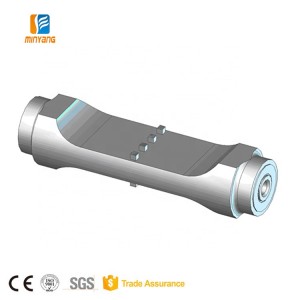

Common ultrasonic mold materials are aluminum alloy, steel and titanium alloy, different materials suitable for different application and products to be welded. Also, aluminum alloy, steel and titanium alloy horns have their advantages and disadvantages. We will choose the high quality material for your products.

Our ultrasonic mold has below features:

1. we will choose the high quality ultrasonic mold material for plug

2. We can manufacture ultrasonic mold according to plug samples or drawing.

3. The welding effect is good, and will not break the electronic components inside of the plug.

4. we will do the ANSYS testing for our molds

5. The ultrasonic horn/mold is strong and durable.

Advantages

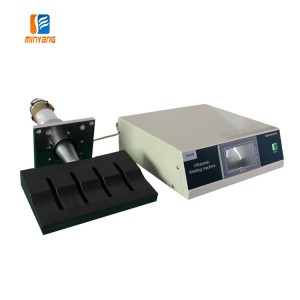

Quick ---- each welding time 0.01-9.99 seconds.

Strength to withstand large pulling force, high pressure.

Quality ---- watertight, airtight, hermetically welded, not to hurt the plastic pieces during welding.

Economic ---- without screws, glue. Reduce labor, low cost.

Applications

Widely used in different kinds of ultrasonic equipments including ultrasonic welding machine, ultrasonic plastic welder, ultrasonic metal welding machine, Ultrasonic high frequency welding machine, ultrasonic spot welder, ultrasonic embossing machine and so on.

Factory Show

Certification

FAQ

A: Yes, we can. The mould could be customized based on your samples, the voltage can be 110V or 220V, the plug can be replaced with yours before shipment.

A: Please provide the material, size of your product and your welding requirements, such as waterproof, tight air, etc. You'd better provide product 3D drawings , and we can help to check if the drawings need to be changed. So that the plastic product design could meet the requirements of ultrasonic welding technology.