Ultrasonic spin welding machine for PE PP nylon PET round or tubular workpiece welding

Specification

| Model | MY-SP2715 |

| Power | 1500w |

| Voltage | 110/220v |

| Net Weight | 200kg |

| Machine Size | 890*760*180mm |

| Warranty | 1 year |

| Welding Time | 0.01-9.99S |

Features

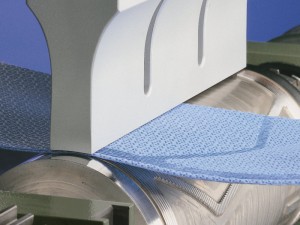

Spin welding is a process that joins circular thermoplastic parts by bringing the part interfaces together, under pressure, with a circular, spinning motion. One part is held stationary in a fixture, while the other is rotated against it under pressure. The frictional heat that is generated causes the part interfaces to melt and fuse together, creating a strong, hermetic seal.

1. Most suitable for welding sphere and cylinder plastic pieces of any size.

2. Most suitable for welding thermoplastics with low hear conductivity.

3. Cost effective and secure, energy efficient.

4. It is easy to set up and operate.

5. Can be configured to manual, semi-automated, or fully- automated

Factory Show

Certifications and Patents

FAQ

A: Yes, we can. The mould could be customized based on your samples, the voltage can be 110V or 220V, the plug can be replaced with yours before shipment.

A: Please provide the material, size of your product and your welding requirements, such as waterproof, tight air, etc. You'd better provide product 3D drawings , and we can help to check if the drawings need to be changed. So that the plastic product design could meet the requirements of ultrasonic welding technology.

Applications

Spin welding machine is suitable for welding of tube-like or round shape products (PE/PP/PET/Nylon) Such asdewatering joint,engine filter bowl,filter,float gage,ice cup etc.