Hot Products

Innovation

ABOUT US

Breakthrough

yilong

INTRODUCTION

Mingyang ultrasonic equipment factory is a manufacturer and we have specialized in the production of ultrasonic welding machine for over 20 years.

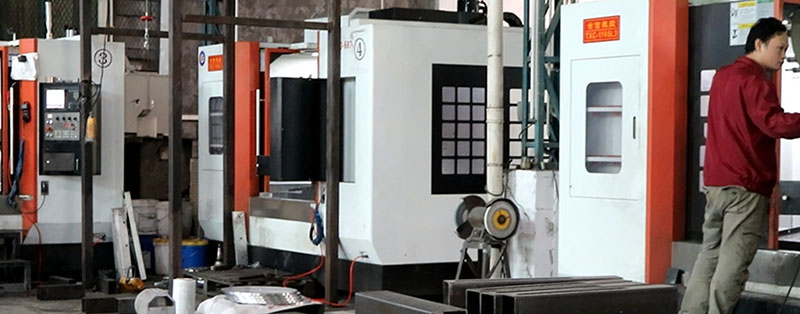

Factory: Our factory is located in the China industry city–Guangdong. As a global supplier that can provide a series of plastic welding solutions, we have exported our equipment to 56 countries and won the trust of customers.

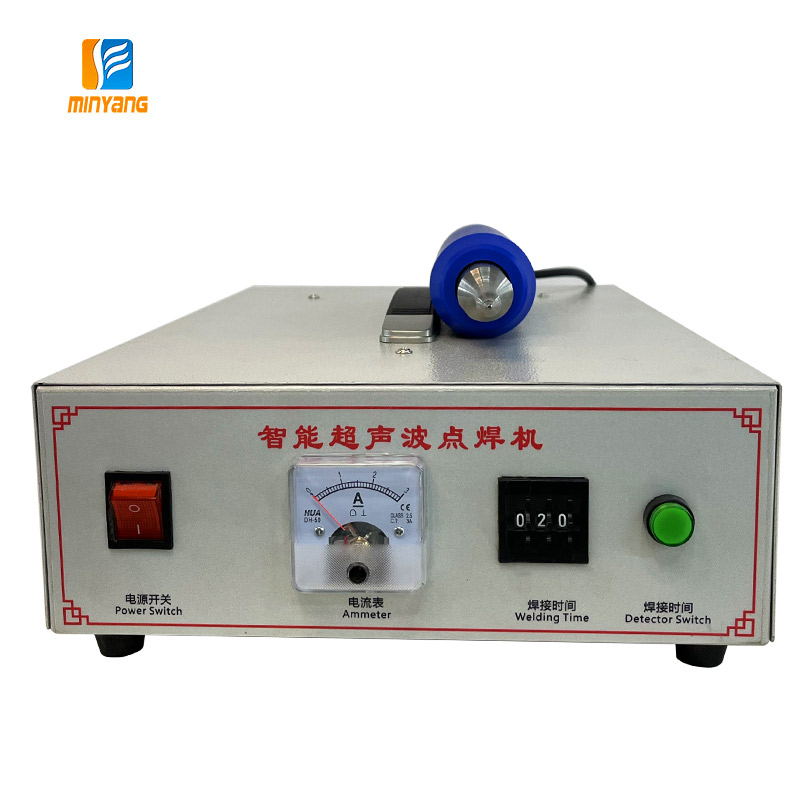

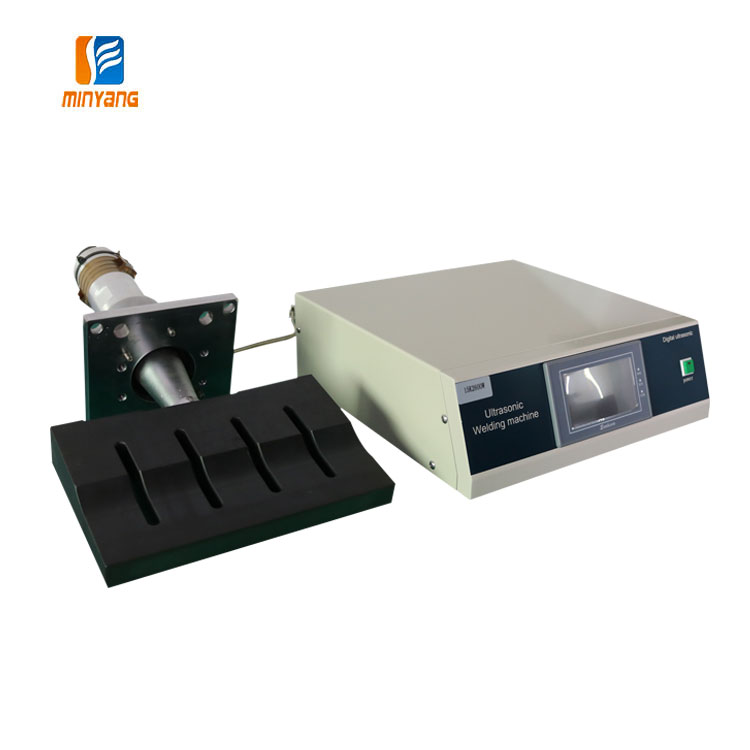

Products: Ultrasonic welding machine, ultrasonic generator, high frequency welding machine, hot melting machine, spin welding machine, other customized ultrasonic machine etc.

Certification: We have passed ISO9001 certification, and all the machines passed CE and other certifications(according to your requirement).

Service: We can provide free welding technical solutions from the beginning of the plastic project to the product is produced perfectly, and support free welding samples. we have a long-term after-sales service team.

-

-Founded in 2014

-

-7 years experience

-

-+5000 ㎡ large plant

-

-H24-hour consulting service

We do for you

From your project idea to application development to process optimization, we will work together with customers to create the best solution. We firmly believe that we have appropriate experts and excellent ultrasonic solutions for each application You only need to provide the drawings and requirements of the product.

We do for you

We have more than ten engineers who carry out R & D, experiment and application of ultrasonic welding in different industries. We have obtained more than 10 patent applications and have been recognized by the state as an R & D enterprise. Therefore, we are your best partner.

We do for you

Our innovative ultrasonic technology will help you achieve sustainable development goals, because ultrasonic technology is a reliable technology that saves extremely resources. Enables you to reduce waste, material use, and energy consumption.

Thanks to this unique combination, let's work together to achieve your business success! "

We do for you

As our company philosophy, we are committed to providing reliable, safe and fast services to customers and providing immediate support in more than 20 countries / regions. For you, this means that we can provide support quickly when you really need help.

NEWS

Service First

-

How does an ultrasonic welding machine actually weld plastic?

First, let’s discuss the principle of ultrasonic welding machines: They convert 50/60 Hz electrical current into high-frequency electrical energy (such as 15, 20, 30, or 40 KHz) through an ultrasonic generator. This electrical energy is then transformed into mechanical motion of the same fr...

-

Principle of ultrasonic metal welding machine

Principle of ultrasonic metal welding machine Used for secondary connection equipment of metal products. 1.Overview of ultrasonic metal welding: Ultrasonic metal welding equipment referred to as ultrasonic gold welding machine. Ultrasonic metal welding technology was dis...

-

High frequency welding machine

High frequency inductive machine is referred to as "high frequency welder", also known as "high frequency induction heating equipment", high frequency induction heating machine, high frequency induction heating device, high frequency heating power supply, high frequency ...

-

Case | Dynamic contact analysis of ultrasonic plastic welding

In this example, the thermoplastic bonding method “ultrasonic plastic welding method” was used to predict the dynamic behavior of cylindrical plastic parts during the bonding process by dynamic contact analysis of finite element method, and the relationship between driving frequency a...

-

Is it really waterproof? Ultrasonic for welding plastic products?

In the daily ultrasonic processing and welding process, there are often plastic processing manufacturers question: is ultrasonic welding plastic really waterproof? According to MingYang ultrasonic nearly 30 years of ultrasonic welding experience: plastic welding can be w...

-

Not waterproof? After welding the plastic with ultrasonic welder?

Many customers will ask us a question, why the products welded by the ultrasonic welding machine we used before cannot achieve air tightness and water resistance? For ultrasonic welding of plastic products, because of the differences in product function and function, the...